Pad printing

About the Technique

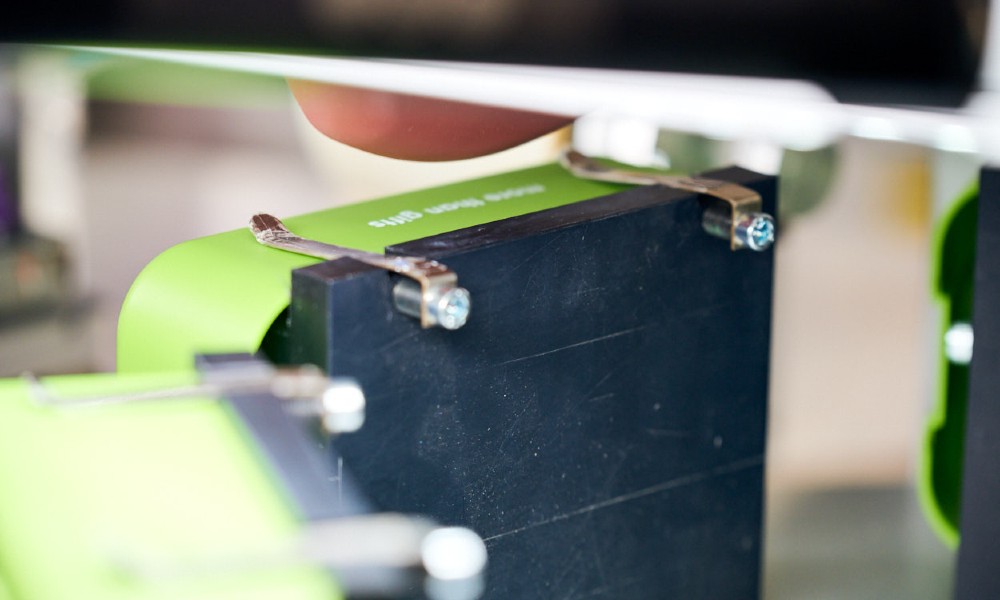

Pad printing is one of the most widely used branding technologies for promotional products. In this process, ink is transferred from an engraved metal plate (cliché) onto the product using a flexible silicone pad. Thanks to the pad’s adaptability, this technique allows printing on hard and uneven surfaces – whether flat, concave, convex, or curved.

This method is ideal for precise, high-resolution branding with accurate Pantone colour matching, even for logos and fine text on small print areas.

Key Advantages

- Compatible with almost all materials: plastics (PP, PS, PE, PVC), metal, glass, ceramic, wood, paper

- Suitable for all types of shapes, including complex and miniature items

- Enables exact PMS (Pantone Matching System) colour accuracy

- Allows up to 4–5 separate colours

- Provides a sharp, detailed finish

- Durable – e.g., up to 30 dishwasher cycles at 50°C on glass

Ideal Products

- Pad printing is ideal for small, hard-surface promotional items, such as:

- Promotional pens – plastic, metal, or eco-materials

- USB sticks, keychains, lighters

- Desk accessories – business card holders, clocks, memo holders

- Ceramic and glass mugs (depending on shape and coating)

- Calculators, rulers, memo clips

- Bathroom accessories, compact mirrors, cases and pouches

Technical Considerations

- Recommended maximum logo size: 90 mm diameter (varies by item)

- Supports only solid Pantone colours – no gradients

- Each colour is applied separately

- Post-treatment may be required for hard plastics, metal, or soft-touch surfaces

Environmental and Safety Aspects

- No water usage

- High energy consumption and VOC (volatile organic compound) emissions

- Generates significant waste, including hazardous residues

- Some inks comply with GRS standards, though metallic inks are not GRS-compliant

Why Choose GD novelty?

Durable and clean prints

Vibrant and accurate colours

Perfect adaptability to difficult surfaces and product shapes

Whether you're branding corporate pens, trade show giveaways, or personalized accessories, pad printing remains a reliable and refined solution for durable branding on compact items.